Effect of Temperature on the Evolution of Physical Structure and Chemical Properties of Bio-char Derived from Co-pyrolysis of Lignin with High-Density Polyethylene

11:01 - 25/03/2019

Natural durability of the culturally and historically important timber: Erythrophleum fordii wood against white-rot fungi

Shrinkage and swelling behavior of archaeological waterlogged wood preserved with slightly crosslinked sodium polyacrylate

Natural durability of Erythrophleum fordii Oliver against white rot fungi

Shrinkage and swelling behavior of archaeological waterlogged wood treated with polyacrylic acid resin

Authors

- Weimin Chen - Nanjing Forestry University

- Shukai Shi - Nanjing Forestry University

- Thiphuong Nguyen - Nanjing Forestry University

- Minzhi Chen - Nanjing Forestry University

- Xiaoyan Zhou - Nanjing Forestry University

Abstract

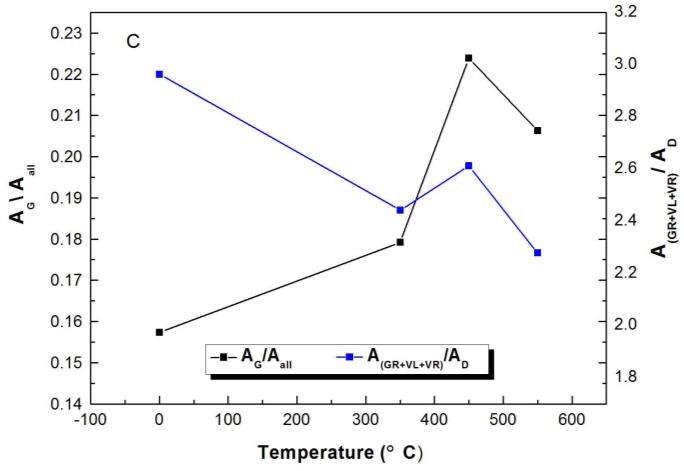

Bio-chars were produced by co-pyrolysis of lignin with high-density polyethylene at 350 °C, 450 °C, and 550 °C. X-ray diffraction (XRD), Raman spectroscopy, automated surface area and pore size analysis, scanning electron microscopy (SEM), Fourier transform infrared (FT-IR) spectroscopy, X-ray photoelectron spectroscopy (XPS), and electron spin resonance (ESR) spectroscopy were performed on bio-char to reveal the effect of temperature on its physical structure and chemical properties. All of the bio-chars demonstrated a highly disordered, turbostratic structure and exhibited a wide pore distribution. Dramatic losses of carbonyl, hydroxyl, and C-H groups indicated the development of condensed aromatic structure in the bio-chars. Specifically, biochar produced at 450 °C showed the highest degree of aromaticity, which is the relative content of aromatic structure with small fused rings and free radical concentration. This structure has more potential application in composite production and as solid fuel for its combustion or gasification. Moreover, biochar produced at 550 °C had the greatest porosity development, favoring its use as a precursor for activated carbon production.